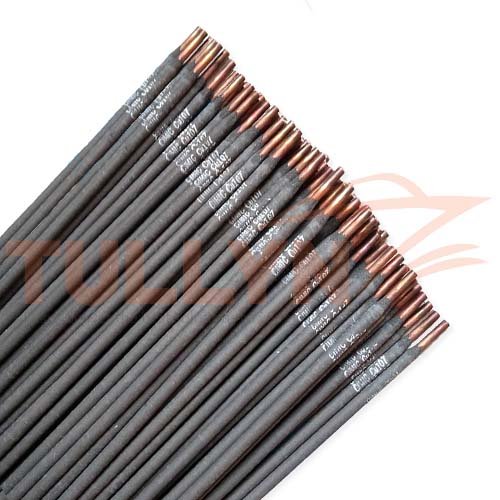

ECuSi Silicon Bronze Welding Electrode

ECuSi Silicon Bronze Welding Electrode Application

ECuSi Electrode performs well in any position utilizing AC as well as DC machines. ECuSi weld deposits are strong, ductile and crack resistant-even welding on dirty, oily, burned cast or maliable pars. The high silicon content of this electrode allows it to be used as a welding or brazing electrode.

ECuSi flux coated electrodes are used for welding or building-up silicon bronze as other copper alloys. It is an excellent choice for applications involving cast iron to steel where the part is exposed to corrosives. ECuSi is commonly used on bronze impellers, bronze wear plates, hydraulic piston overlays, track wheels, gears, sprockets, and quite often farm implements.

ECuSi Silicon Bronze Welding Electrode Typical Chemical Composition

| Cu | Fe | Si | Sn | Mn | Pb | Others |

| Bal. | 0.50 max | 2.4-4.0 | 1.5 max | 1.5 max | 0.02 max | 0.50 max |

Mechanical Properties

| Yield Point | Tensile Strength | Elongation | Hardness |

| N/mm2 (ksi) | N/mm2 (ksi) | % | HB |

| 250 (36) | 420 (61) | 25 | 80-100 |

ECuSi Silicon Bronze Welding Electrode Typical Welding Parameters

| Dia. | 2.5 | 3.2 | 4 | 5 |

| Length | 250 | 350 | 350 | 350 |

| Current Range Amp DC (+) |

50-70 | 70-110 | 100-150 | 140-180 |

Please note that the above specifications are “general specifications” that pertain to the majority of our production. These specifications should only be used for general, informational purposes. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All specifications are subject to change without prior notice. All pictures shown are for illustration purposes only. Actual product may vary.

Reviews

There are no reviews yet.